Maintenance Guide

Caution

Eyes harzard. Risk of eye injury.

(PPE) Personal Protective Equipment required. Wear safety glasses and nitrile gloves.

Important

The customer is responsible for all the items on the checklist and must to follow all the procedures related below to ensure good equipment operation and quality output jobs.

Daily Maintenance Requirement

Important

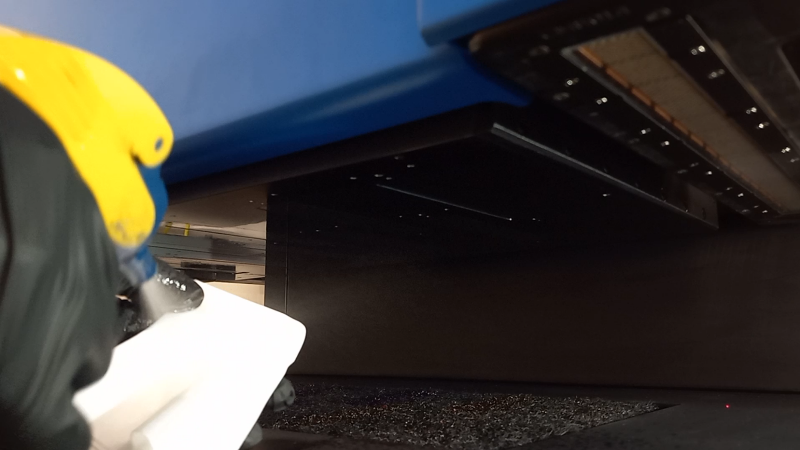

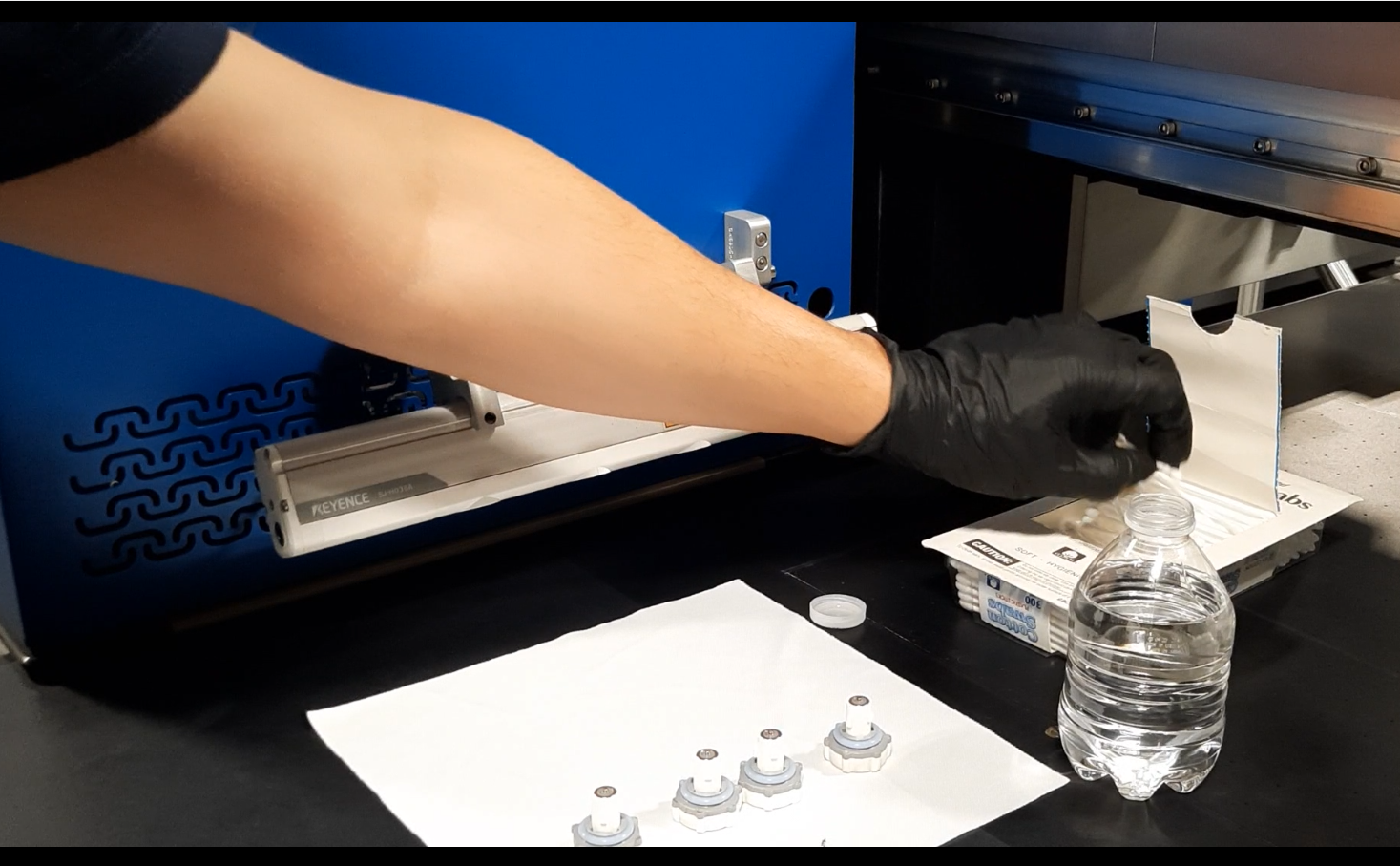

Wipe the heads with lint free embed TruFire Flush. Follow the [Video] for a full reference xxxx

Important

Wipe the printhead plate with lint free embed Trufire Flush. Follow the [Video] for a full reference xxxx

Caution

Do not leave the printheads with flush for long period of time. Prime the heads is mandatory after wiping the printheads with flush.

Important

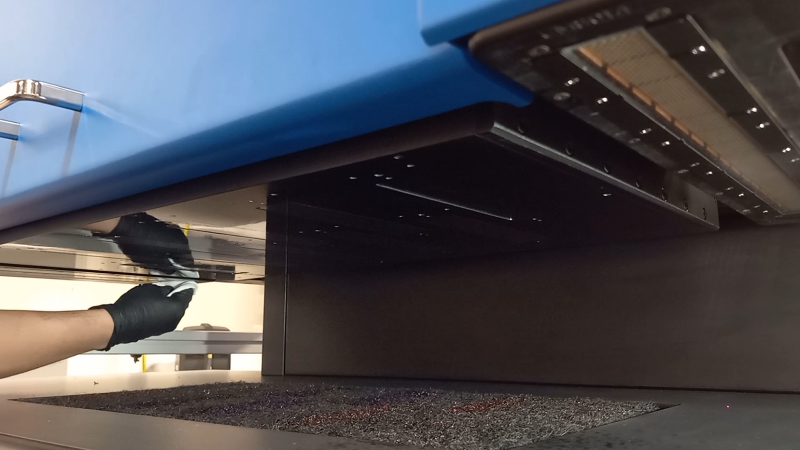

Wipe the UV lamps with lint free embed IPA (isopropyl alcohol 99%) Follow the [Video] for a full reference xxxx

Important

Wipe the head crash sensors with lint free embed IPA (isopropyl alcohol 99%) Follow the [Video] for a full reference xxxx

Important

Wipe the lamp covers with IPA alcohol.

Important

Wipe the home area with IPA alcohol.

Important

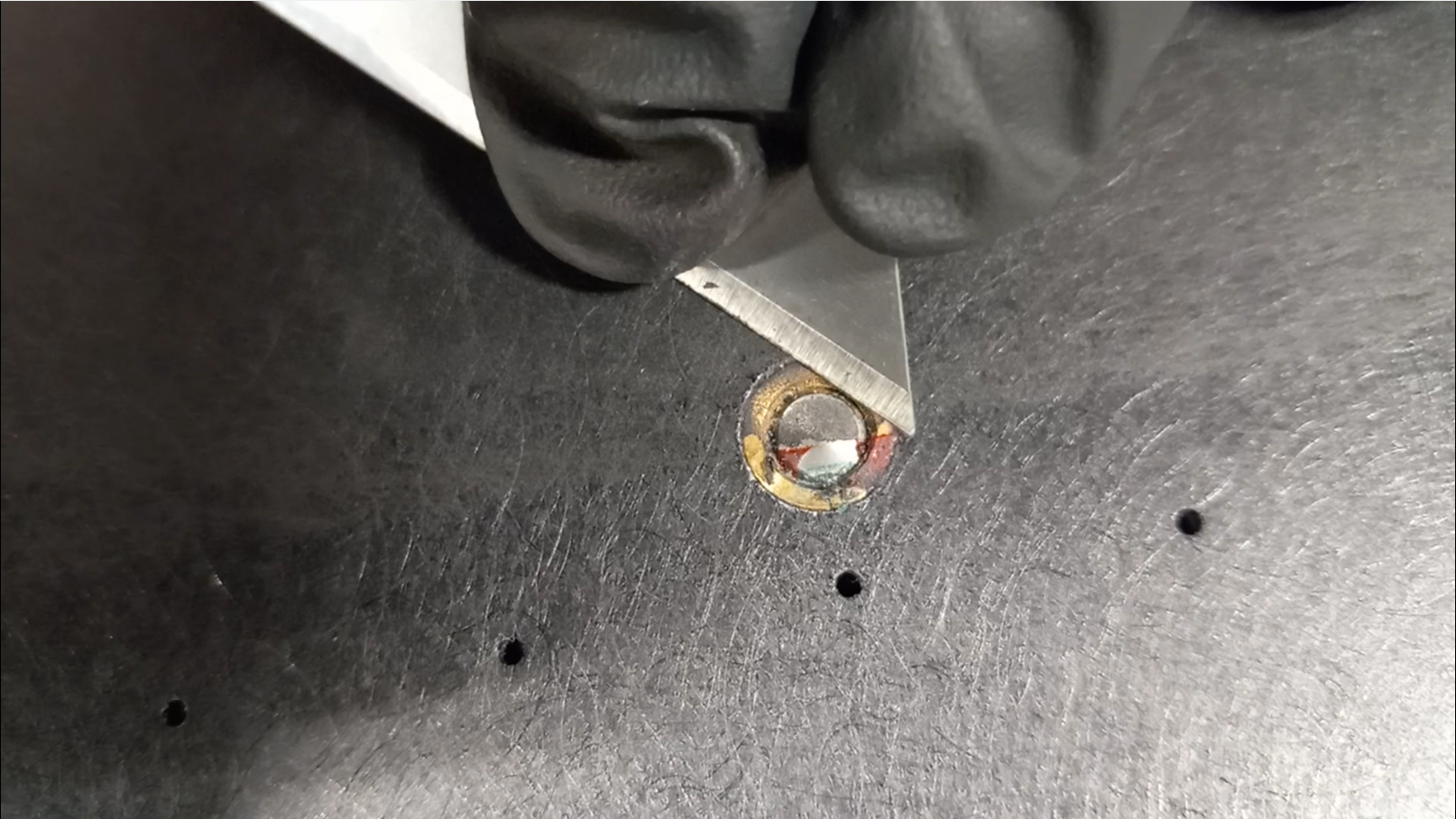

Remove cure ink residues from the table. Follow the [Video] for a full reference xxxx

Important

Remove cure ink from the pins. Follow the [Video] for a full reference xxxx

Important

Wipe entire equipment

Keep the equipment clean and dust-free.

Daily White Procedure

Make sure the white valve is ON allowing the white ink to recirculate.

Make sure the bucket has enough white ink (850 level as a minimum) otherwise, the re- circulation will turn off.

Once a week Maintenance Requirement

Important

The following checklist must be completed before to start production day.

The customer is responsible for all the items on the checklist and must to follow all the procedures related below to ensure good equipment operation and quality output jobs.

Changing fans and UV lamps filters

Important

Clog filters can cause overheating electronics, low performance and damage the boards. Maintenance type: Preventive Maintenance Frequency: Once a week

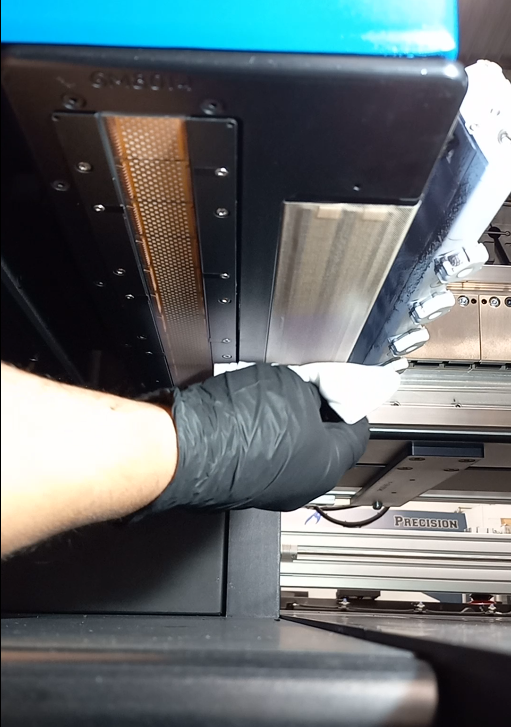

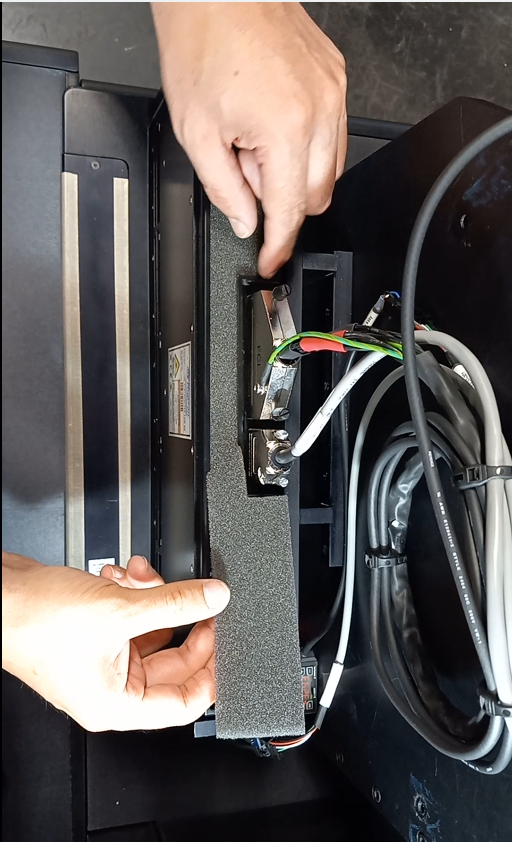

Wiping the Ionizer bar

Important

Dirty nozzles will cause low performance and static issues. Maintenance type: Preventive Maintenance Frequency: Once a week

Turn off the Ionizer power from the GUI

Unplug the ionizer nozzle

Wipe the ionizer nozzle with a cute tip embed with IPA

Plug back in the ionizer nozzle

Turn on the Ionizer power from the GUI

Follow the [Video] for a full reference xxxx

Waste Bucket Maintenance

Important

Full bucket may overflow.

Maintenance type: Preventive

Maintenance Frequency: Every two weeks

Place a 5 gallon bucket under the waste bucket located at the left side underneath the printhead carriage.

Important

Waste ink is classified as industrial waste. Dispose of waste ink according to your local laws and regulations such as entrusting it to an industrial waste disposal company.

Open the valve to drain out the ink.

When finish close the valve and wipe the drain valve.

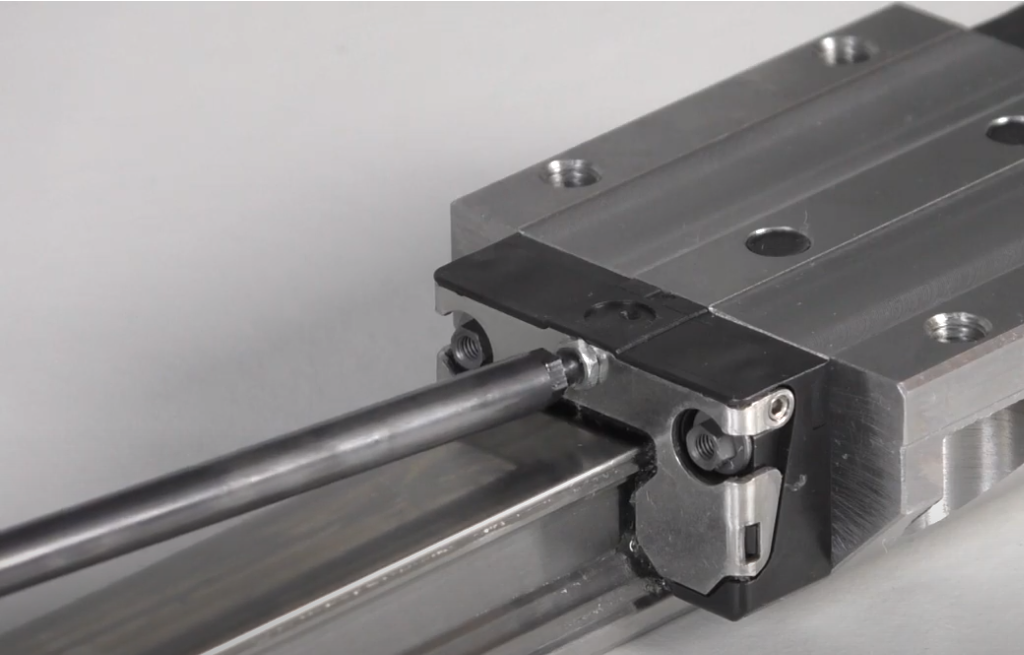

Greasing the bearings

Important

Maintenance type: Preventive

Maintenance Frequency: Every two weeks

Follow the [Video] for a full reference

Changing ink filters

Important

Clog filters will cause ink starvation.

Maintenance type: Preventive

Maintenance Frequency: 1 month- 3 months - 6 months. Depending of operating hours the interval will be more frequent.